|

This is a solution from Karen Donde's workshop on how to control a second warp. This shows the second warp going over the raddle and weighted separately in sections with water bottles. |

Note - This article was written by Suzanne W. of Reno Fiber Guild. The photos from the workshop will be posted in Part 2 on this blog. You will read about how each weaver handled the two warps that were required to weave Turned Beiderwand and other turned tied weaves possible on the same threading in this workshop. Warping was probably the most difficult aspect of the whole workshop. TBW will be the abbreviation for Turned Beiderwand in this article.

Turned Beiderwand with Karen Donde was an excellent weaving workshop. Karen taught us so much more than what the TBW structure is. She taught and demonstrated how versatile the TBW threading was by altering either the tie-up and/or the treadling, we were able to weave a myriad of other structures. Given the time and inclination, one could get lost in that rabbit hole in a very long time!

Several things that I (Suzanne) especially liked about the workshop was:

We learned that TBW is a unit weave. I love unit weaves for their design capabilities as you can hop to any block to create a design vs. following a prescribed progression to avoid exceedingly long floats in your warp. Note: Since the BW draft is turned, all floats are in the warp.

We learned to read and understand our drafts in relation to blocks. With 8 shafts, you have 3 pattern blocks available. Each pattern block requires two shafts. The ground warp ends are threaded on shafts 1 and 2, leaving shafts 3-8 for pattern blocks. Easy Peasy… keeping track of treadling and designing as its all “tied” to your blocks!

We learned about Ratios and how to adjust them. Yes, traditional TBW had long warp floats: but, we learned multiple ways to shorten those floats for a choice of purpose and fabrics. Example with a 1:4 Ratio you’ll end up with a 9-end warp float, but the floats alternate between the two pattern shafts so that you have a tie-down (ground warp) every 5th pick. Consequently, those long ends are densely set and staggered - not all hanging loosely to get snagged. As for a serviceable fabric, again that depends on your objective and the fibers used. My ground warp is 20/2 Tencel and my pattern warp is 10/2 Tencel, both are sett at 30 epi. With a 20/2 weft, my fabric has a very nice hand and is plenty stable for a scarf. In short, ratio = # of tie-down threads to the number of pattern pics!

Because this was a Zoom 3-Day Workshop vs. an in-person workshop, during our break on our last day we held a round-robin discussion about what looms we used, fiber, warping method, problems and tips. Note: Most of us with floor jack looms (raising shafts) had to weave everything upside down as more shafts were going up vs. staying down. Those with Dobby or Sinking Shed looms were seeing the right-side of their fabric as they wove. The rest of us didn’t see that front side until it was off the loom!

Diane – 8-Shaft David with a sinking shed. She wove her fabric RIGHT side up! Fiber 20/2 ground Tencel and doubled 20/2 tencel for pattern. Both warps wound unto back beam w/o any issue. Pattern warp tension holding fine as of the last woven sample. The consensus was that sinking shed looms have less issue with displacing the tension on the pattern warp.

Joan – 8-Shaft David with a sinking shed & 2 back beams! Warps 10/2 and 5/2 and an exploration of color with yarns in stash!

Irene – Louet Spring w/2 back beams. Warps 8/2 tencel and 10/2 cotton. Had a mis-threaded section and thought she’d threaded wrong as was getting such long floats! She cut off, fixed the mis-threading to start again. Mystery problem w/loom when trying to advance warp.

Kathy – AVL Home Loom with 2 back beams. 10/2 Cotton and 8/2 Tencel. No problems to report!

Teddie – Baby Wolf 1 back beam with both warps wound unto back beam. Had a minor issue with separating the two warps to put in a weighted dowel, but then okay. 10/2 Tencel and 8/2 Tencel.

Maggie – Baby Wolf 1 back beam. Had tension issues at the start. Stopped and re-tied on. 10/2 Cotton and 5/2 Cotton.

Karen – Aristat Leclerc/1 back beam. Didn’t report any tension issues. 10/2 ground and 8/2 cotton.

Betsy – Baby Wolf 1 back beam. Followed Karen’s video to the “T”! Her pattern warp was NOT wound unto the back beam but weighted in sections with S-hooks and filled water bottles. No tension issues! 10/2 Cotton for both warps.

Sharlet – Fireside 2 back beams. Because of the loom design, it was difficult to hang separate sets of lease sticks to see to thread! 10/2 cotton for both warps. See Sharlet’s use of Kumi plastic bobbins for missing warp ends! Holes in the bobbins make it easy to attach weights.

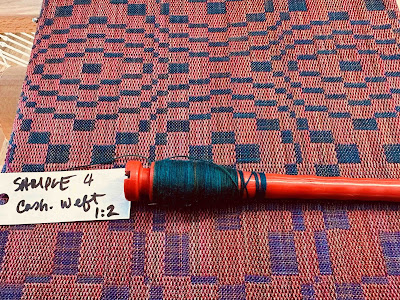

Shelley – Mighty Wolf 1 back beam. Followed Karen’s video to the “T” and even left in the raddle on the back which helped with the tension of her pattern warp. Note: The raddle was raised above the ground warp. All was great! 10/2 and 5/2 yarns.

Deb – Table Loom- 2 back beams. 10/2 cotton and 5/2 cotton. No issue with tension.

Suzanne – Baby Wolf 1 back beam. Wound both warps with 1/1 cross unto beam. Separated warps with weighted dowel after 1st yard to keep tension on pattern warp. The only pesky issue was advancing the warps once weighted. To advance, I needed to un-weight, advance, and then re-weight. But then the AVL double-back beam required getting up and down to adjust. 20/2 Tencel and 10/2 Tencel. I will definitely have more JOY weaving future TBW’s on the AVL so that I can see the face of the fabric while weaving vs. the back!

In the next blog post, you will see multiple versions of the following structures: Turned Biederwand, Turned Extended Summer & Winter, Turned Summer & Winter, Turned Even and Uneven Tied Overshot, Turned Half Dukagang, Turned Paired-Tie Weave, Doubleweaves, and lastly Double 2-Tie Units. Everyone's favorite look

for the contrast, texture and sharpness in the design was Turned Half Dukagang, but not the

easiest to treadle and is why the samples are so short!

Keep in mind that everyone received a different draft and used recommend setts for yarns in their stash. The overall favored structure for its durability was the summer and winters as it had the least floats and the cleanest lines. Another favorite for its textural contrast and sharpness of design was the Turned Half Dukagang. Very pretty but not the quickest to treadle; hence, the shorter samples! Photos, which will be shared in the next blog post, are from the group as they posted into Padlet.