Hemp Facts

Hemp, like flax, is a bast fiber plant, characterized by strong, cellulosic fiber found in the outer layer of the plant. The woody interior is called the hurd. Decortication is the process of separating the bast from the hurd, which is an arduous task; the stalks are tough and the plant is held together by pectins or glues. A mechanized decorticator uses grinders, rollers, blades, and other such tools to shatter or break the hurd into small bits, separating it from the fiber. Hurds can be utilized to make ceiling panels, bedding materials, hempcrete, and other industrial products while bast is used to make clothing, textiles, ropes, home furnishings, and shoes, to name a few.

Retting is the process of breaking down the pectins, either through field retting (drying in the field), water retting (soaking), or chemical retting. Modern decorticators can bypass the retting phase and process freshly harvested stalks.

Day One...How Do We Get Spinnable Fiber From The Hemp Plant?

In the HEMP BY HAND workshop, we did not have the benefit of a decorticator, and experimented with freshly harvested stalks that were placed into a steamer to release some of the pectins (traditionally accomplished by retting), allowing us to extract fibers from the fresh stalks. There is a historical precedent for steaming the stalks, as researched revealed for Stephenie Gaustad, our workshop leader.

This process of harvesting fiber from fresh stalks is time-consuming with a learning curve, but not impossible. Certainly, for industrial use, such a cottage approach would not be practical; however, for small artisan projects, it is feasible. The HEMP BY HAND workshop experimented with several methods:

- peeling the outer cortical layer from the stalk and then separating the fibers from the resulting ‘ribbon’;

- scraping the outer cortical layer to extract individual fibers;

- using stalks dried over night to break the hurd from the cortical ‘ribbons’ and then separate fibers.

Industrial stalks are 4-6 feet in length and marked with nodes, the parts in a plant that connect new stem offshoots with older growth, such as a branch, a leaf, or even a bud. This was a spot where the fibers were likely to break, resulting in a shorter staple length, certainly a disadvantage of hand processing. Online videos show commercial fibers the full length of the stalk, one of the great benefits of hemp as a fiber for spinning.Nonetheless, when we examined the commercial sliver, the length of the fiber matched the length between nodes on the industrial plant and produced an easily spinnable length (4-6 inches)

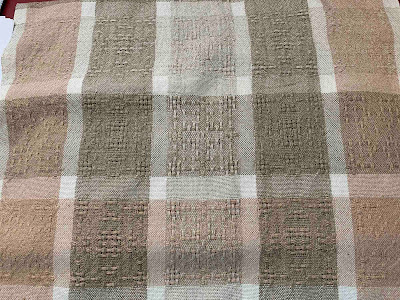

The fibers we harvested from the workshop would need more processing to produce spinnable fiber: traditionally, once the fibers have been separated from the stalk, scutching is required, which involves beating the fiber bundles to further separate raw materials from other particles (outside skin, bits of hurd, etc). This is followed by “hackling,” which combs shorter or broken fibers out of the bundles and aligns them into a continuous sliver for spinning. We experimented with combing and found it immediately produced a softer fiber, although more work would be required to get the fiber ready to spin. Because of time constraints, we used commercially produced sliver. It produced a lovely yarn, lustrous and strong. The more hemp yarn/fabric is washed, the softer it becomes, similar to linen. There was discussion about the ease of using hemp as a botanical dye, as well as how well hemp takes commercial or other botanical dyes. Some of the participants took plant material home to experiment with it as a dye, and Stephenie indicated hemp takes dye as well as any bast fiber.

Day Two...How Do We Use Hemp for Basketry?

On the second day of the workshop, we focused on producing fibers for basket-making and rope-making. We had the benefit of both freshly steamed stalks and yesterday’s steamed stalks (the effect of which allowed the dried hurd to be more easily removed). The basket-makers found the fresh fibers a very workable source for cordage; some experimentation with dried fibers indicated the complexities of retting: too dry and the fibers were brittle or broken down.

In general, the basket-makers were accustomed to acquiring and processing raw plant material, so they jumped into the process quickly and experimented with how damp or dry the material should be to work most efficiently. For smooth “green” cordage, they found the steamed stalks produced fiber that twisted smoothly and easily into cordage. Cordage from the dried plants (from last year’s harvest and thus “brown” in color) produced a rougher ply, and would probably benefit from hackling to remove the harsher bits still attached to the fibers. Both produced very strong cordage.

The consensus among the basket-makers was that hemp was strong, attractive, and flexible, being less prone to breakage than other fibers. Working with hemp was new and thus cumbersome, but as many pointed out, all plants require their own learning curve to successfully process. Industrial hemp was compared with Apocynum (dogbane or “Indian hemp”), which does not have a woody interior and thus was much easier to process. The biggest limitation to working with hemp was its availability for the small scale artisan.

The dried CBD plant (versus the industrial stalk) produced a surprising result; the short, bushy plant was from last year’s harvest and thus was quite dry and not amenable to ease of extraction of fiber. Stephenie Gaustad (workshop leader) placed several stalks in a black plastic bag, set it out in the sun for a few hours, and long, flexible wet fibers were easily extracted. That was a big surprise to all of us, but occurred at the end of the day and would require further exploration.

We also discussed the possibility of using the stalk for basketry, but the dried stalk was fairly brittle and most believed it would not be useful for traditional basketry forms—perhaps some non-traditional basketry might use the stalks for low-stress frames. The participants identified that the industrial stalk was hardest at its base, while more flexible at the top. The best fibers (stronger, longer) seemed to be found at the bottom of the plant, while the fibers got increasingly thin and more difficult to extract toward the top of the plant.

Take Home Thoughts

In closing, all agreed that the workshop was informative, educational, and ‘food for thought.’ Many wanted to pursue hemp as a fiber, while others felt it was too labor intensive. Several participants took plants/fiber home with them to experiment with more processing.

In terms of overall goals, we believe the workshop was ‘ground-breaking’ and successful:

1.The workshop successfully introduced the hemp fiber plant to local spinners, weavers, knitters, and basket-makers. For many, hemp is an unknown plant, cloaked in anecdotal beliefs about its origins and uses. Our workshop showed that hemp is a viable fiber plant and a legitimate and

worthwhile endeavor.

2. The workshop opened the door to further exploration of hemp. We successfully established a working relationship with an industrial hemp grower, and we plan to continue to build that relationship to create viable hemp fiber for our region.

3. The workshop is a strong example of ‘nothing beats experience’. We can read about processing hemp all we want, but until we get our hands on it, it is only an abstraction. This workshop sets the stage for more hemp education and experience, be it dying the yarn, refining the fiber, or creating local Fibershed products.